Landing pads for prefabricated panels

Inflatable shock absorbers for handling prefabricated building components – provided by FabriQ

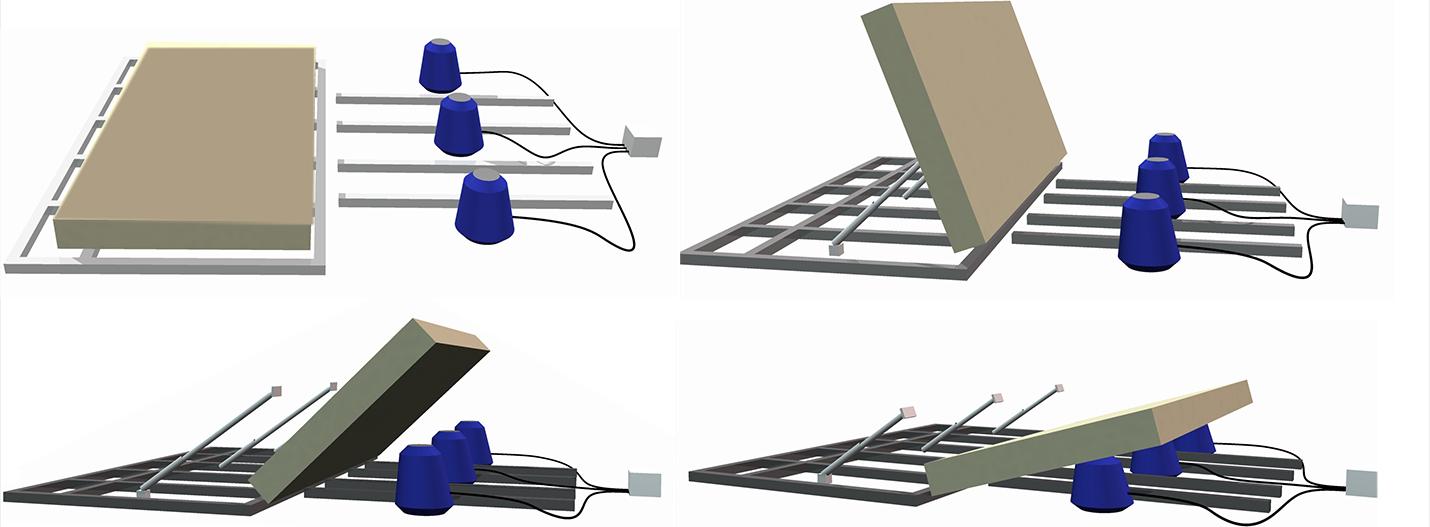

In production lines for prefabricated building components, such as wooden floors , the elements often need to be tilted or rotated to be able to treat the underside. This applies to both coating and finishing , and is a challenge when the parts vary in size, weight and construction.

The challenge

Traditional solutions, such as robotic arms and grippers, can be very complex and expensive , especially when the components have different dimensions and geometries. A simple, safe and cost-effective method was needed to support and cushion the building components during the tilting process.

The solution from FabriQ and Buitink Technology

FabriQ Innovation AS , in collaboration with Buitink Technology , has developed an inflatable shock absorber system that is integrated directly into the production line. The system consists of inflatable cushions that automatically adapt to shape and weight, and act as a shock-absorbing surface when parts are tilted or lowered.

Advantages of the solution:

-

Flexible handling of different component sizes

-

Gentle support that reduces the risk of injury

-

Reduces the need for expensive robotic solutions

-

Low investment cost and easy integration into existing production

-

Can be adapted to different production environments and layouts

The solution is particularly well suited for the production of:

-

Floor elements

-

Wall modules

-

Ceiling panels

-

Other prefabricated structural elements

Do you want a customized solution adapted to your production line?

FabriQ Innovation AS delivers complete systems – from idea and design to finished solution. Contact us for more information or technical support.

This system of inflatable screens is lightweight, flexible, compact in the uninflated state and effortlessly absorbs all major impacts during crashes of the prefabricated parts.

In addition, the inflatable shock absorber is a low-pressure system (the internal pressure never exceeds 500 mbar) and therefore very safe to use.

The inflatable impact cushions are made of a very strong (TPU) coated tarpaulin (type IV-VII, with a breaking strength of 7,000 - 13,000 N/5 cm) with high puncture resistance. Furthermore, the inflatable cushion is equipped with air connections and adjustable pressure relief valves, which release the pressure from the cushion in the event of an impact.

We also supply the cushions including an air installation with control, which keeps the cushions at the correct pressure and can be connected to the customer's automated production system.

Inflatable cushion system

As also shown in the video here, the next steps in using the collection blocks are:

- Tilting floor boards weighing not less than 2,800 kg each;

- When a floor section passes the tipping point, it must be received;

- Buitink Technology has developed a system of cushions to capture the sections;

- The cushions act as shock absorbers.

Pris oppgis ved forespørsel