Tailor-made underwater habitats

What is an underwater habitat?

An underwater habitat is a temporary structure used to create an enclosed, dry work area underwater. This space is pressurized with air so that work such as welding or sealant repairs can be carried out safely and efficiently - even at great depths.

Our habitats are lightweight, flexible and easy to install manually around your desired workstation.

What are our habitats used for?

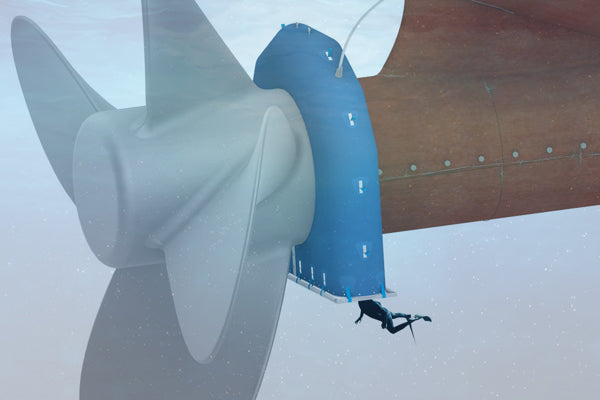

Our underwater habitats are used worldwide for all types of repairs and inspections on or under ships, oil rigs and other maritime installations.

- Repairs to seals

- Bow and stern propellers

- Propeller repairs

- Hull repairs

- Pipe structures

- Exhaust gas cleaning

- Specific applications and forms

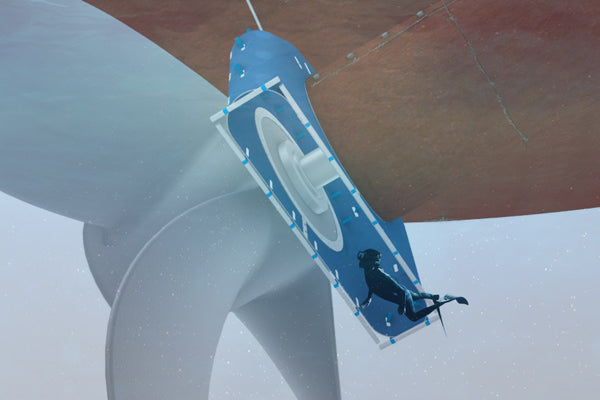

Top air connection - safe ventilation above water

Our underwater habitats are equipped with a strategically placed air connection on the top. This ensures controlled ventilation of excess air and guarantees stable overpressure in the habitat. This keeps the work area dry and safe, even during prolonged underwater work.

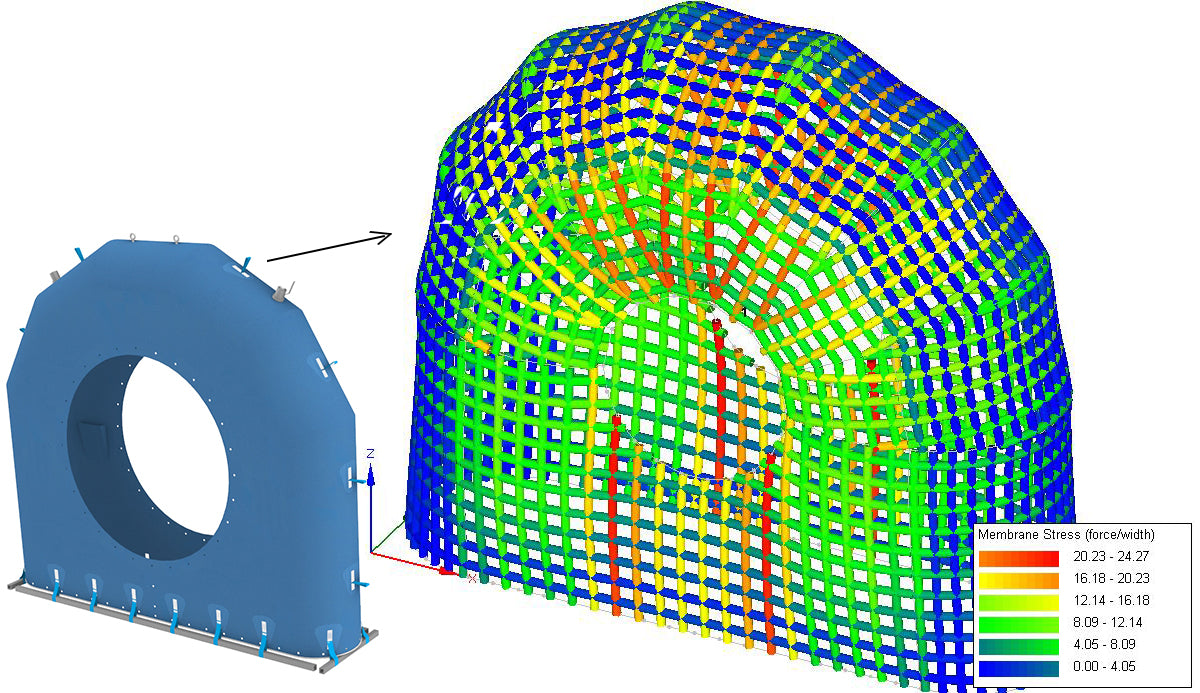

Project planning and design

We model the desired shape and dimensions of the habitat and carefully analyze the forces and stresses in the fabric that occur underwater, in a static situation. In this way, we guarantee a safe and functional design, fully tailored to the specific application.

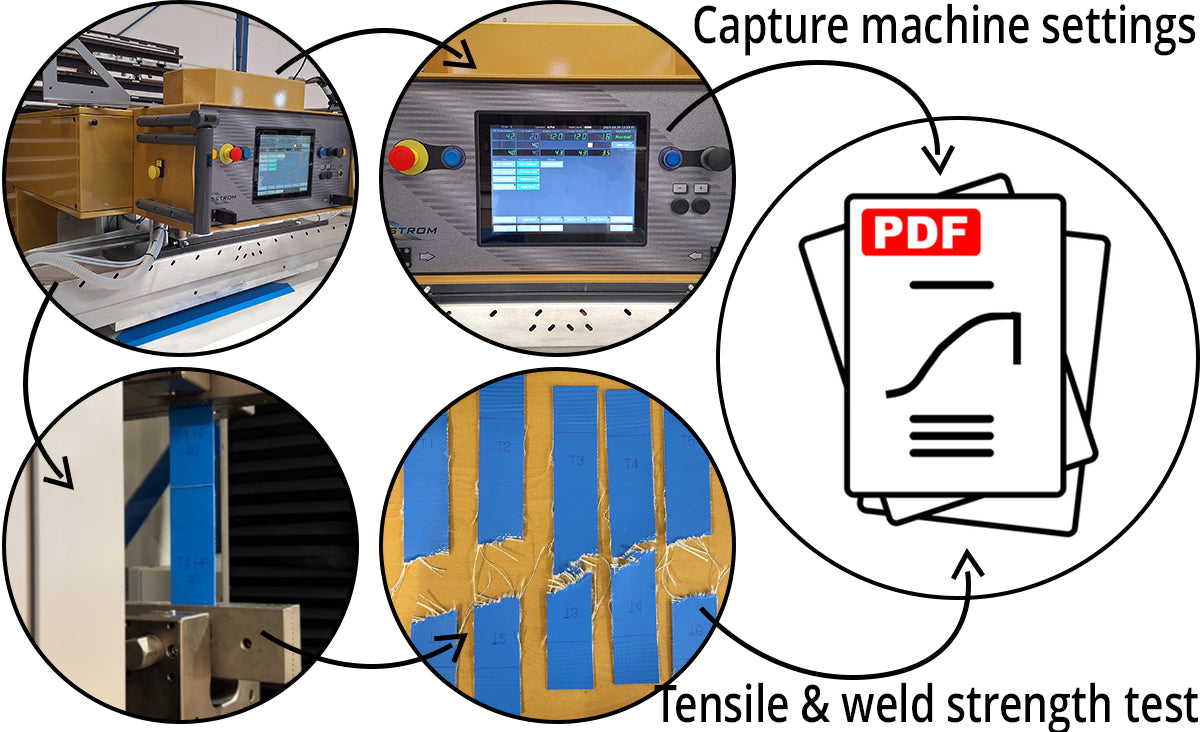

Quality and control during the production process

During the production process, we ensure quality by performing interim tests and carefully recording all machine settings used.

For example, settings for high-frequency welding machines are specifically determined, tested and documented for each type of weld and habitat. This way we guarantee a consistent and reliable finish on every product.

est and verification of the final product

We give each habitat a unique, non-erasable product number. This number allows us to track exactly when and by whom the habitat was manufactured, and which materials and batches of materials were used.

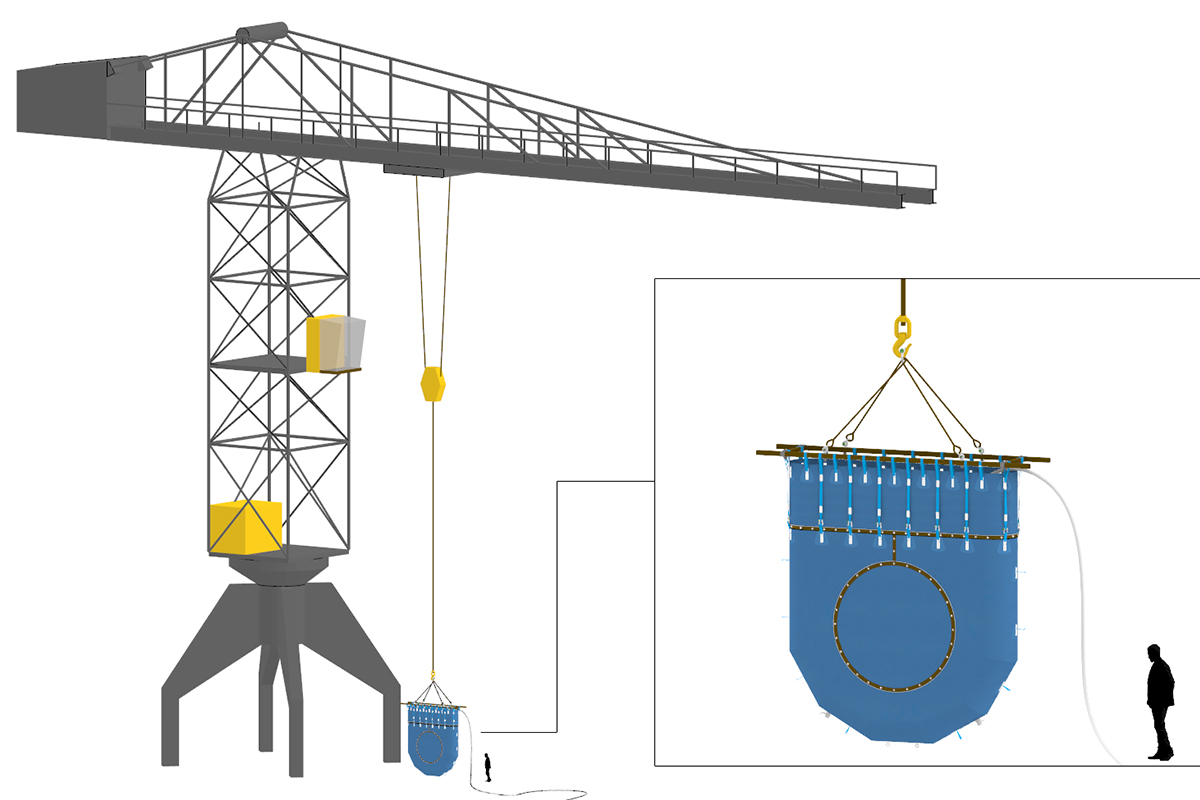

If necessary, we also conduct periodic checks of habitats that have been in use. Furthermore, in certain situations - for example when developing a new model - it is desirable to test the habitat for the actual stresses that occur.

We have developed a specific test procedure for these tests, which is explained in the images below.

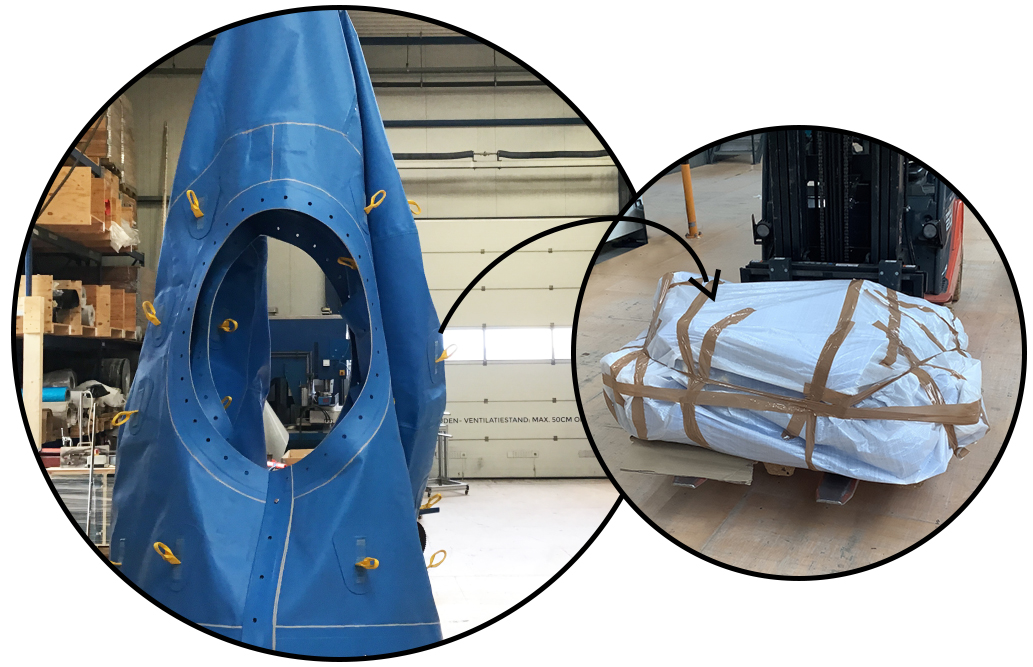

Production habitat completed

The habitat is fully manufactured, carefully folded and compactly packed on a pallet - ready for transport to its new destination.

Pris oppgis ved forespørsel