Inflatable CO2 emission reducing valve

Operation and purpose of CO2 emission reduction

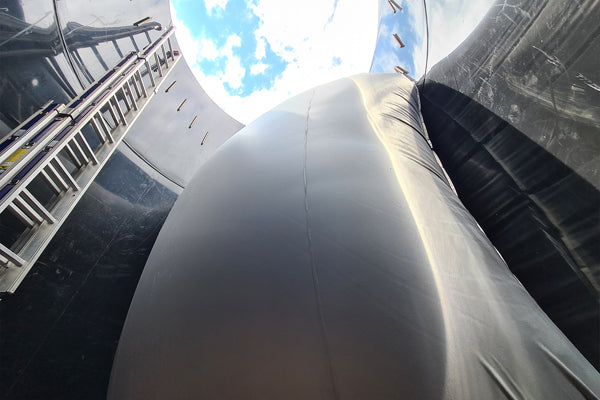

The purpose of Buitink Technology's heat-resistant inflatable valve is to reduce energy and heat loss and cut CO2 emissions from industrial chimneys.

When a factory or a production process stops – for example during maintenance work – a chimney that is temporarily out of service can often cause large unwanted emissions of heat and CO 2 .

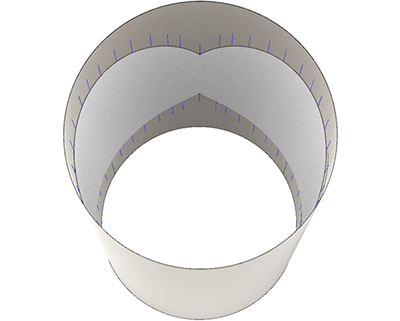

It is at these times that Buitink Technology's inflatable CO2 Emissions Reduction Devices can be automatically or manually filled with air, closing the chimney and preventing hot air from escaping.

Inflating the chimney emission reduction valve

The video here shows the inflatable CO2 emission reducer being inflated.

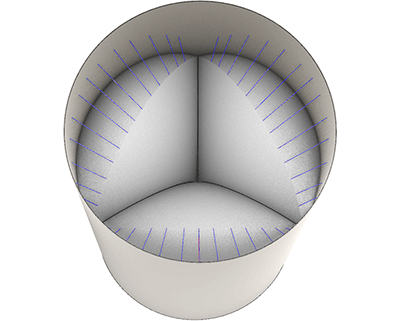

The reason why Buitink Technology's inflatable CO2 emission reducers are such a good choice is that they are compact and lightweight, meaning they are relatively easy to retrofit into existing industrial chimneys.

Furthermore, our inflatable chimney flaps become very flat when deflated and are kept flush with the chimney wall. This means that there is virtually no narrowing of the chimney opening, so they do not obstruct the passage and release of combustion gases.

Sustainable: heat retention and reduced CO2 emissions

Many of Buitink Technology's products and solutions actively contribute to reducing CO2 emissions . This is especially true of our inflatable CO2 emission reducer for industrial chimney stacks.

A real-world example demonstrates the enormous energy savings and carbon emission reductions that can be achieved with a CO2 reduction system from Buitink Technology.

Robust, heat-resistant and resistant to air currents

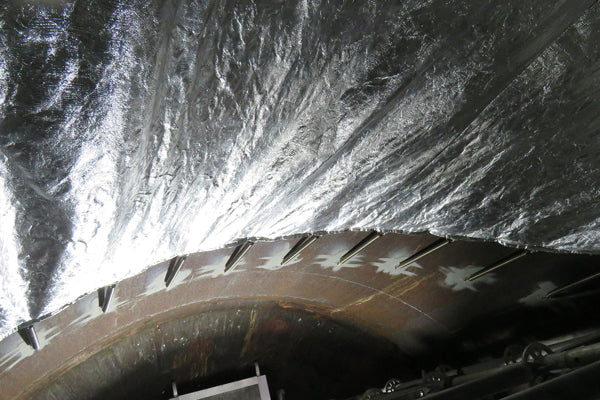

An inflatable CO2 reduction system from Buitink Technology that is installed in industrial chimney stacks is robust, heat-resistant and able to absorb the necessary forces created by air movements in the stack.

Our choice of the right materials from which the valves are constructed depends on environmental factors such as size, chimney diameter, maximum temperature and forces acting on the inflatable valves.

We also design the attachment points from which the valves are suspended in the chimney. After we have designed the attachment points, we run extensive internal tests on them in our test machine.

Construction from special materials

Our selection of suitable materials to manufacture an inflatable CO2 emission reducer depends on the situation and the specific circumstances. We design the fastening and installation system to cope with the specific forces that the inflatable valve will be subjected to.

For example, construction and choice of materials must take into account:

- Operating temperatures (minimum and maximum temperature in the chimney stack);

- Composition of the gases;

- Air velocities in the chimney stack and consequently the required material strength;

- Other requirements, such as minimizing the risk of explosion caused by friction (we make the outer shell of the CO2 reducer from a fabric with an antistatic coating).

Turnkey delivery, including automatic and manual controls

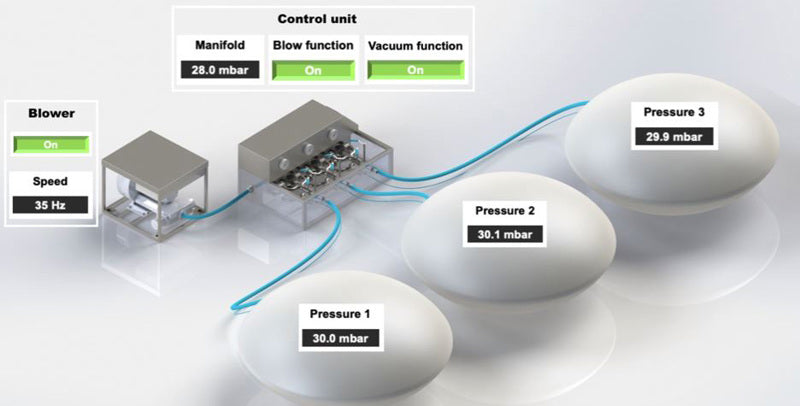

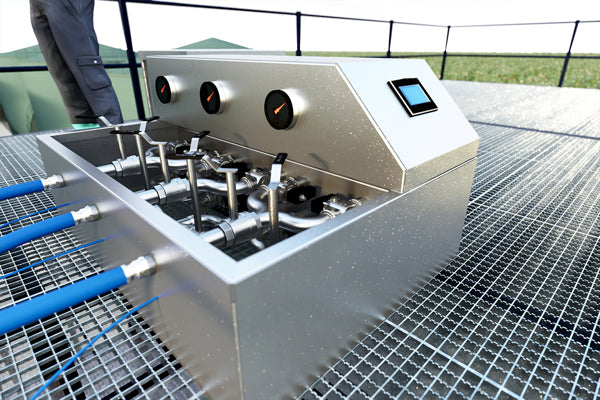

We can supply a fully operational inflatable CO2 reduction system with all necessary components: inflatable reducers, electric valves, air lines, measuring lines, fittings, manifold, air installation with automatic controls and remote monitoring and operation.

The control dashboard for the three inflatable CO2 - emission reducing: The pressure can be set and monitored. The entire system is automatically inflated and maintained at the correct pressure.

The air system we supply not only fills the inflatable valves with air, it keeps them at the correct pressure and deflates them after use.

Our air systems can also be operated manually using the manifold and pressure gauges provided. When the system is first put into operation, the correct settings (especially the pressure) usually need to be found. This is first done manually and then stored and programmed into the software that controls the system automatically.

Factory tested

We are able to test the system at our location in Duiven to minimize the risks during commissioning. The testing takes into account the application, situation, assumptions and requirements of our tailor-made inflatable CO2 emission reduction system.

The assembly and installation of the system often involves a lot of preparation, and it is expensive to shut down a factory process to install the valves. Therefore, if we are still unsure about some aspects of how the system will work, we simulate the assembly process and the operation of the valves as closely as possible in our premises. The situation in which the system will work and how it will be used will determine whether this testing process is necessary or worth undertaking.

In addition to real-world testing, we can also model the operation of our inflatable CO2 emission reducer and provide a statement of the forces that exist in the chimney stack and act on the chimney wall.

Prefabrication, packaging and shipping

We deliver our prefabricated products worldwide. This also applies to our inflatable CO2 emission reducer. We can design, manufacture and supply all the components required for commissioning, adjustment and operation of the system, so that they are ready to use right out of the box. We can also supervise the installation anywhere in the world.

Our inflatable CO2 emission reducers are compact and lightweight and can be shipped relatively easily and cheaply by air, sea or road.

Benefits of our inflatable CO2 emission reduction system

An inflatable carbon monoxide with Buitink technology 2 -The emission reduction system has several important features that give it an advantage over alternative solutions.

- With a relatively low investment you can save a lot of energy and cut CO2 emissions .

- An inflatable CO2 emission reducer made by Buitink Technology is compact, very lightweight, foldable, flexible and can therefore be retrofitted into almost any industrial chimney stack;

- When the air has not been sucked out by the CO2 reducer , it lies flat and tight against the chimney wall, so it hardly impedes the free flow of combustion gases at all.

- We can deliver our prefabricated, plug-and-play inflatable CO2 emission reducer anywhere in the world;

- Buitink Technology's inflatable CO2 emission reduction system can be monitored and controlled remotely;

- A major advantage of these inflatable valves is that they require very little maintenance. The inflatable valve is operated by a central air system that inflates it to close the chimney or sucks the air out of it to open it. The only part that requires maintenance is therefore the central air system. An inflatable valve requires no lubrication, no filter changes, there are no parts that need to be replaced on a regular basis, etc.

Frequently asked questions about the inflatable CO2 emission reduction system

What is the minimum and maximum chimney diameter for which the CO2 emission reduction system is suitable?

Since it is a custom-made system, there are no real limits to the diameter of the chimney that you want it to close. Chimney pipe diameters most often measure between 120 and 360 cm, which is also the range of the systems we have built.

Doesn't the empty CO2 emission reduction system obstruct the airflow in the chimney?

Our system can be permanently installed and remain in the chimney stack because when the valves are not inflated, they are held very tightly against the inner wall of the flue. The mass that can restrict airflow is essentially zero, as our research results confirm.

How quickly can a CO2 emission reduction system be ready for use?

From the moment the air supply is switched on, it takes an average of 4-5 minutes for the CO2 emission reduction to be completely filled and the chimney stack to be completely closed. The filling speed obviously also depends on the internal diameter of the chimney stack.

What temperatures can the CO2 emission reduction system withstand?

Our engineers calculate which materials to build the CO2 Emission Reduction System based on several factors, the most important being temperature and chemical resistance. We have a very wide range of materials to choose from, and sometimes we combine multiple layers to achieve the optimal mix of properties.

Does it take a long time to install a CO2 emission reduction system?

We normally install the system as soon as there is a maintenance shutdown at the production site. With proper preparation, planning and, if necessary, installation supervision by our engineers, we can deliver a complete plug-and-play system that can be up and running in no time.

Is the air supply always included?

For the CO2 emission reduction system to function properly, the inflation, pressure and deflation of the inflatable elements must be carefully controlled. This is best achieved with a dedicated air supply that operates fully automatically and separately from other air systems.

How can we be sure that a CO2 emission reduction system will be a suitable solution for us?

It is clear that every situation is different and conditions can often change. This is why concept testing and simulation of real-world situations are always included in our offer. For example, we can together determine whether a solution we have designed will meet expectations before we install it in your process situation.

Are there any CO2 emission reduction systems that are not permanently mounted in the chimney?

We also supply valves that can be installed and removed at each service. Whether you choose this type of system or a permanent one will mainly depend on the accessibility of the location where the valve needs to be installed. Air is also introduced and removed with each service.

Does the CO2 emission reduction system have a long lifespan?

The lifespan of the CO2 Emission Reduction System will of course depend on how intensively it is used and under what conditions it has to operate. In addition, if parts wear out, we can always carry out maintenance to extend the life of the system. The system consists of very few or no moving parts, so the risk of failure is minimal.

Would our own technical department be able to install a CO2 emission reduction system?

The system consists of a set of inflatable chimney valves and a complete air system which is supplied plug and play to the end user, together with installation instructions. An industrial technical service will normally be able to install it, but our engineers are available to supervise if necessary.

Pris oppgis ved forespørsel