Special lifting bag solutions

Tailor-made lifting cushion systems for critical industrial situations – provided by FabriQ

FabriQ Innovation AS , in collaboration with Buitink Technology , develops and supplies custom inflatable lifting cushion systems for situations where standardized solutions do not exist. These systems are often used in critical industrial scenarios where safety and rapid response are essential.

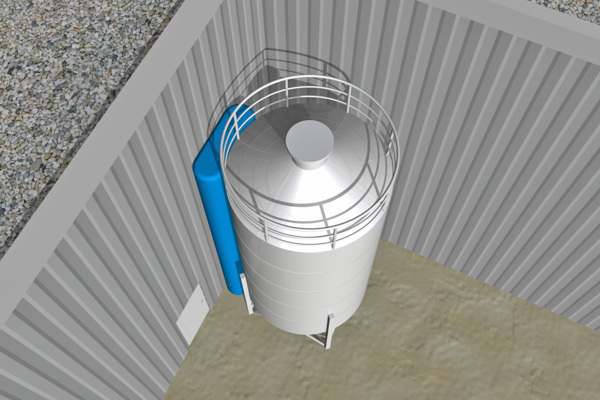

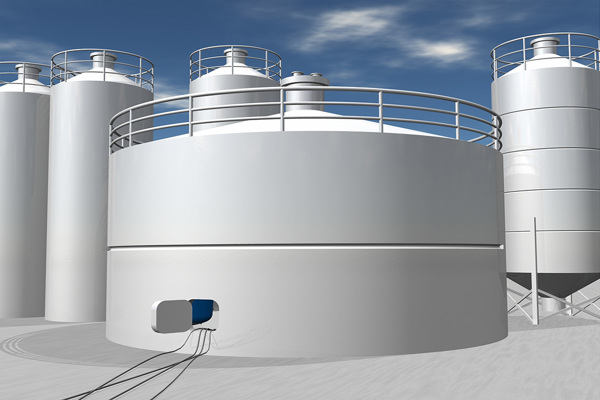

Case: Stabilization of silo at risk of collapse

In this project, a fully loaded silo was in danger of collapsing after the support beams beneath the silo were damaged. The silo began to lean and was heading towards an adjacent building wall – which could have led to major damage and dangerous situations.

The solution: Inflatable support cushion

Buitink Technology engineers developed a specially designed lifting cushion system that was placed between the silo and the building. The cushions provided the necessary lateral support and stabilization, allowing the silo to be emptied safely and in a controlled manner without the risk of collapse.

Advantages of FabriQ's lifting cushion systems:

-

Tailored to shape, load and risk scenario

-

Quick assembly without heavy lifting or intervention

-

Compact and lightweight – ideal for emergencies

-

Can be used as support, lifting or relief

-

Very flexible in shape and placement

FabriQ Innovation AS offers consulting, design and delivery of lifting and support systems for challenging industrial needs.

Contact us for technical specifications or a tailored solution for your project.

Support collapsed roof

This project involves a floating cover for a collapsed chemical silo. The site was an explosive hazard area. In order to work safely inside the silo, Buitink provided a temporary inflatable through the manhole.

For this project, Buitink Technology developed and manufactured 4 lifting bags to provide protection for the workers. Due to the risk of explosion, the bags were inflated with nitrogen. A polyethylene cover protected the bags from benzene vapor.

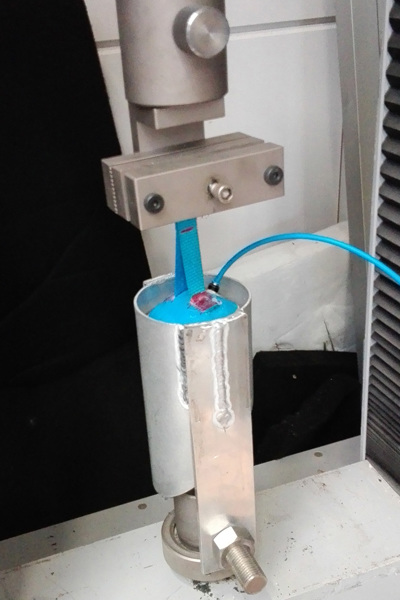

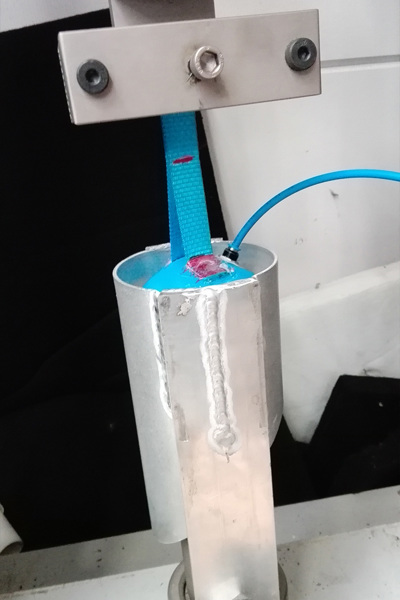

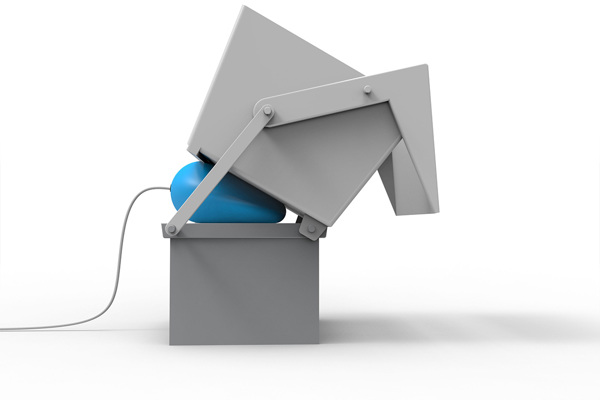

Inflatable lifting mechanism

This lifting mechanism works based on the friction between the contact surface of the bellows and the object to be lifted. This mechanism makes it possible to lift, for example, hollow pipes. The lifting force is by default evenly distributed along the surface, preventing damage to the object. It also makes it possible to lift objects without having lifting connections.

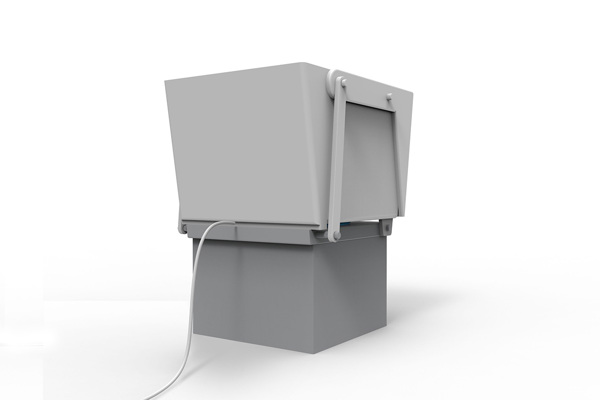

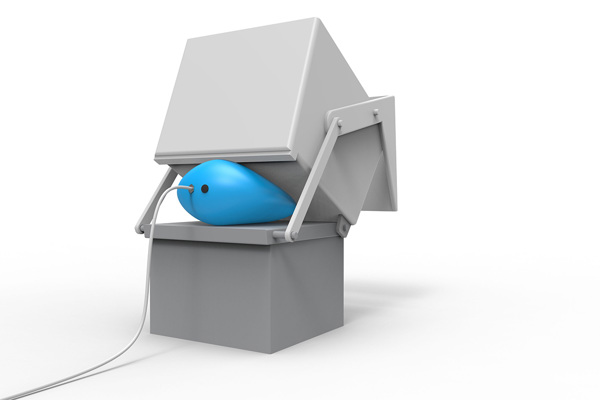

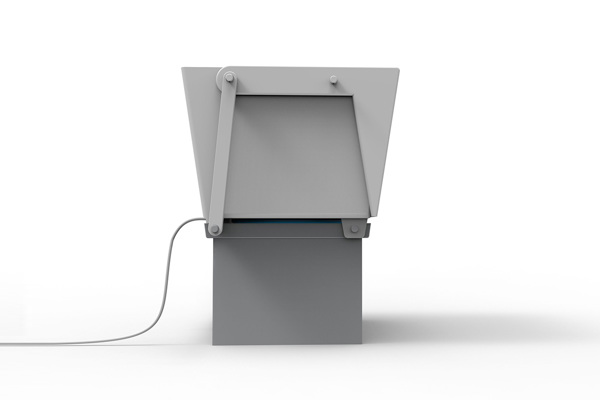

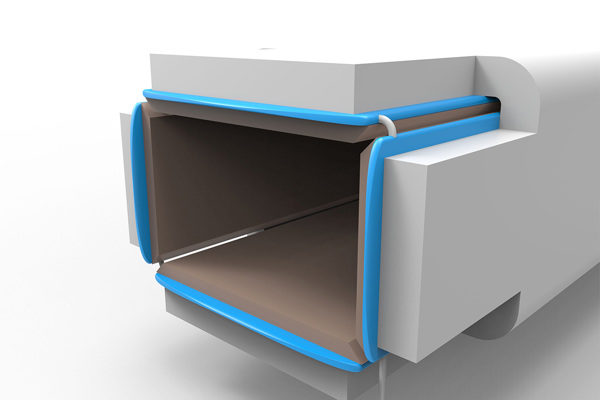

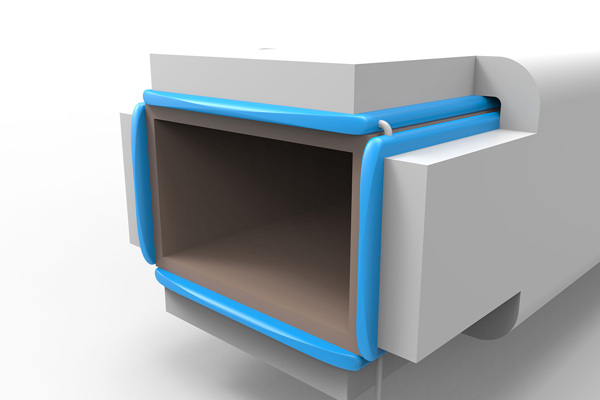

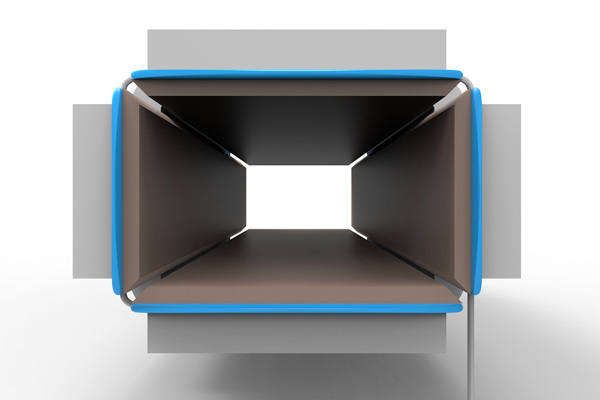

Lifting bags for tilting

Lifting bags can be used in tilting systems. We produce custom lifting bags in various shapes and sizes. The optimal shape and size are determined in cooperation with the customer.

The images below show a nice example of a tilting system where a container is flipped through and inflates a lifting bag.

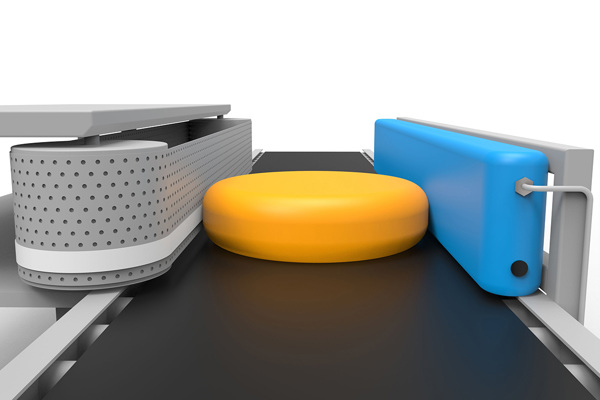

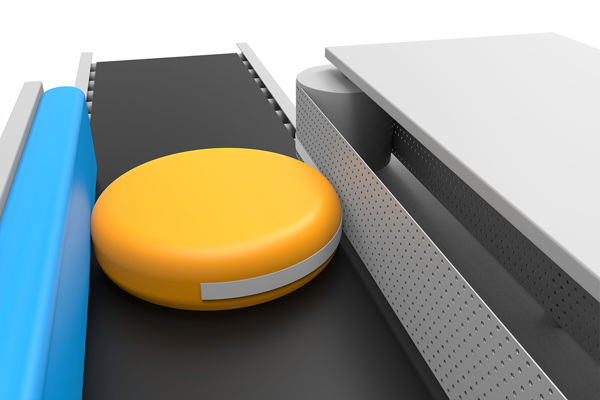

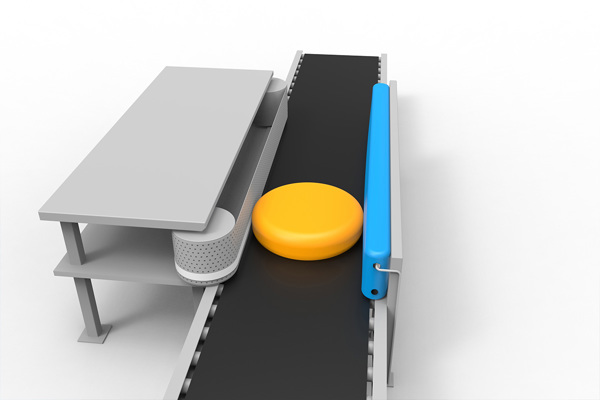

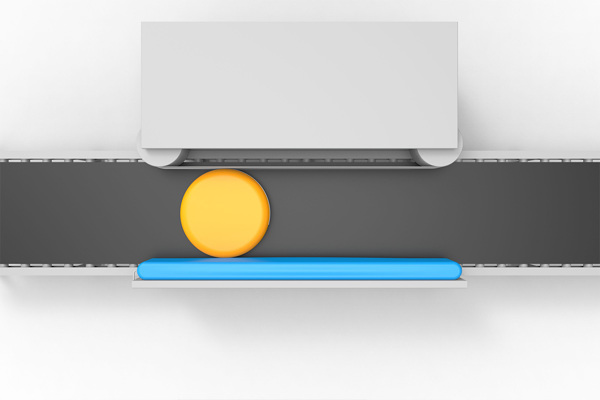

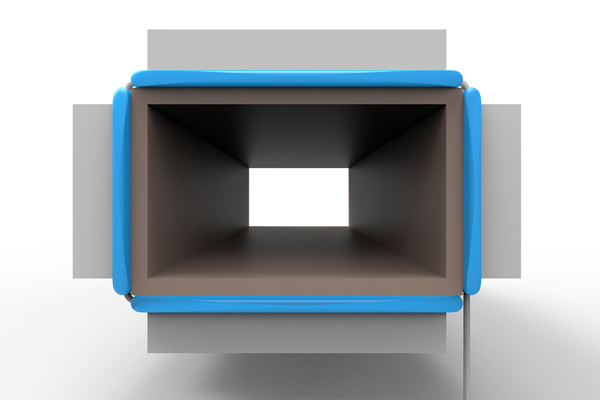

Product press for applying labels

Our inflatable cushions can be used for guidance and evenly distributed pressing; e.g. in the process of labeling cheese. The use of cushions eliminates the risk of damaging relatively soft products.

The images below show a nice example of this system where cheese on a conveyor belt is pressed against the labeling machine using our pneumatic cushion.

Press glue connections

Pneumatic lifting bags are well suited for pressing glued joints without damaging the product. We produce various models in different sizes of lifting bags.

The pictures below show a nice example of this system where 4 different parts are glued and pressed through inflated pneumatic cushions.

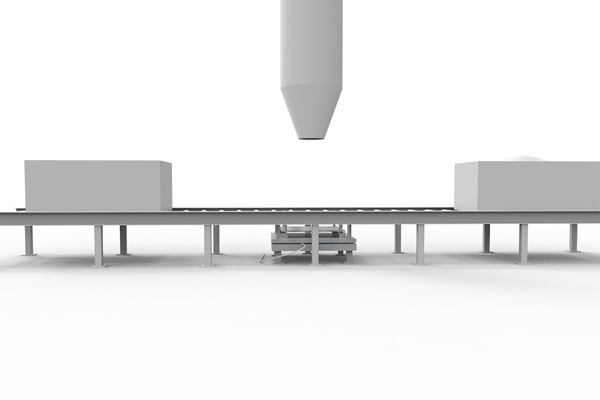

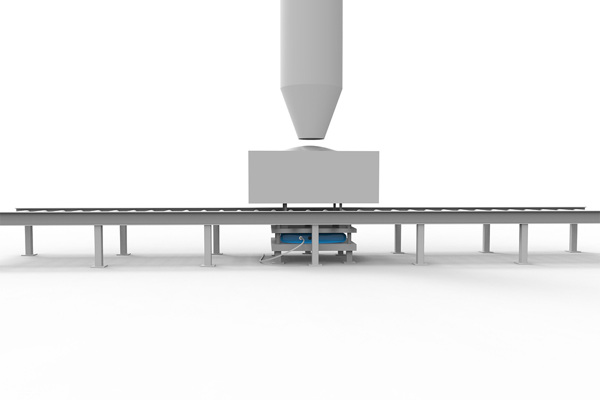

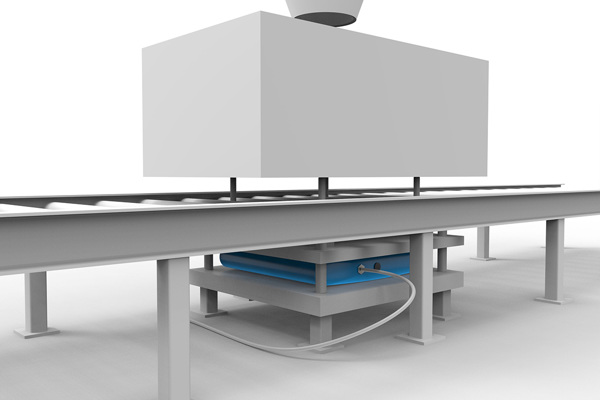

Pneumatic bags for filling process

Lifting bags can be used in processes where solid bulk materials from a silo need to be weighed into containers or big bags through a bagging machine.

An empty container on a belt conveyor under a silo can be lifted off the belt conveyor using an inflatable lifting bag. When the container is full, the bag is deflated to place the container back on the conveyor for further transport.

Pneumatic bags for conveyor belts

An interesting application of inflatable lifting bags is for the crossover of belt conveyor and chain conveyor.

The conveyor belt section between the chain conveyors can be moved up or down through lifting bags. In this way, the transport direction is controlled, either through the belt conveyor or the chain conveyor.

Question?

Pris oppgis ved forespørsel